Update: On October 18, 2023, the USEPA issued an “endangerment finding” under the Clean Air Act, concluding that the “lead emissions from aircraft engines that operate on leaded fuel cause or contribute to air pollution that may reasonably be anticipated to endanger public health and welfare.” The endangerment finding triggers a statutory mandate for the EPA and FAA to develop federal regulations regarding the use of leaded aviation fuel. Read on to learn about the implications of this endangerment finding, as the aviation industry transitions towards unleaded.

AvGas, or aviation gasoline, plays a vital role in the aviation industry, powering the aircraft that connect the world while enabling efficient and safe air transportation. However, there is growing concern over the impact of leaded AvGas on public and environmental health, which is fueling federal, state, and local initiatives to reduce its use and transition to unleaded alternatives.

On the other hand, a transition away from AvGas poses a whole set of challenges, including the complex process of adapting aircraft engines and infrastructure to accommodate unleaded fuels, as well as the considerable costs involved. Nevertheless, the imperative to find alternative solutions is pressing, and addressing these challenges will be key to ensuring a sustainable and cleaner future for aviation.

AvGas Through the Ages

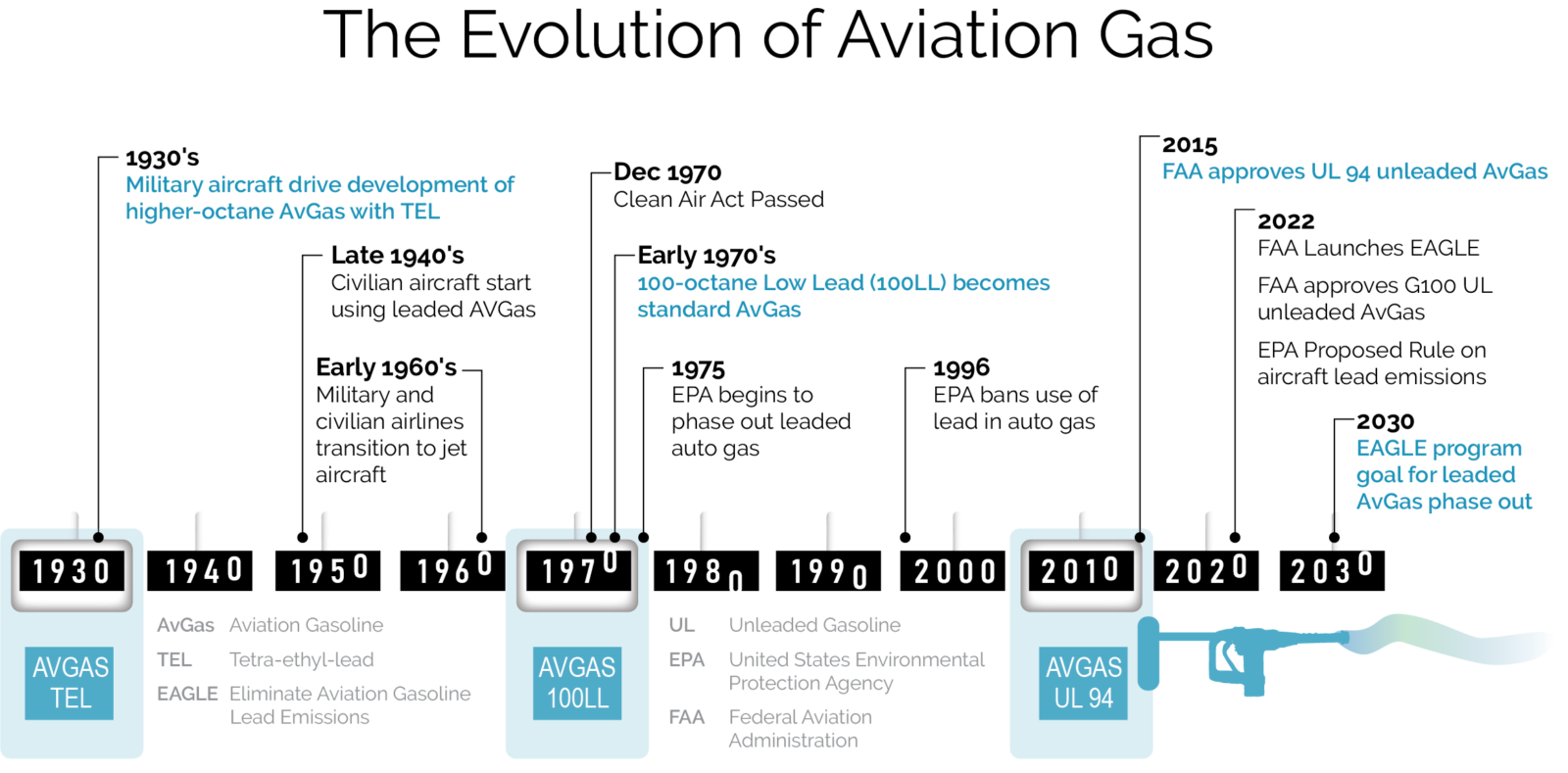

AvGas is a special type of fuel used by many piston-engine aircraft, and its history dates back to the early days of aviation. As aircraft engines became more sophisticated and powerful in the late 1920s and early 1930s, it became clear that higher-octane gasoline was needed to ensure engine performance and reliability.

In the late 1930s, the United States government worked with oil companies to develop a specialized AvGas with a higher-octane rating. The resulting fuel, known as 100-octane gasoline, quickly became the standard for high-performance aircraft, such as fighter planes during World War II. This high-performance gasoline contained tetra-ethyl-lead (TEL) to boost octane and to enable the reliable operation of high-compression piston engines. Since then, TEL has been regularly used as an additive to prevent engine “knock” or premature detonation, which can lead to the failure of critical engine components.

After the transition to jet aircraft for military and civilian airliner fleets, fuel companies converged to one type of AvGas known as 100-octane Low Lead (100LL), which continues to be readily available at most airports with aviation fueling services. Nearly all of the country’s approximately 170,000 active piston-engine aircraft use 100LL, which contains between 0.28 to 0.56 grams of lead per liter of fuel. Given that 100LL can be used by virtually all piston-engine aircraft, this single grade is the only type of fuel consistently available to general aviation (GA) aircraft operators. Consequently, 100LL is also the only fuel that most existing piston-engine aircraft are certified to use by the Federal Aviation Administration (FAA).

Public Health Concerns over Lead Emissions

Lead emissions from the combustion of 100LL in aircraft engines have become a growing concern for the public, especially near airports.

Lead is a toxic metal that can accumulate in the body over time and affect multiple organ systems. In children, exposure to lead can cause developmental delays, learning difficulties, and lower IQ scores. In adults, lead exposure can cause high blood pressure, joint pain, and reproductive problems. Long-term exposure to lead can also increase the risk of kidney damage, anemia, and cancer.

Lead that becomes airborne through fuel combustion is usually in the form of particulate matter and can be inhaled by people in close proximity.

In addition, particles containing lead can deposit onto soil and other surfaces and be ingested through contact with these contaminated surfaces. Deposited lead can also be resuspended into the air as dust and inhaled. Therefore, emissions from piston-engine aircraft that deposited into soil long ago can contribute to present-day lead exposures. Since the use of lead additives in automotive gasoline was banned in 1996, AvGas has become the country’s primary source of lead emissions (about 70% of all current lead emissions).

National Trends in Lead Emissions

For decades, leaded auto gasoline had been the primary source of environmental lead. In 1975, the U.S. Environmental Protection Agency (USEPA) began to phase out the use of TEL as a gasoline additive. The phaseout culminated in 1996 with a ban on the sale of leaded auto gasoline, but it did not apply to leaded AvGas. Between 1970 and 2014, nationwide lead emissions have decreased by 99%, primarily due to elimination of lead additives for auto gasoline.

Although 100LL is widely used by piston-engine aircraft, total leaded fuel use by the general aviation (GA) sector has been on a modest downward trajectory, which tracks closely with a similar, overall decreasing trend in GA aircraft usage. While the downward trend in GA activity will likely yield gradual reductions in lead emissions from AvGas consumption over time, larger, more meaningful reductions will require large-scale adoption of lower-lead or unleaded fuel alternatives to 100LL.

Transitioning to Unleaded Fuels

Currently, UL94 is the only authorized and available unleaded AvGas alternative for GA operators. UL94 can be used in about 65% of the existing piston-engine fleet; however, these aircraft are low performance aircraft that account for only about 30% of the fleet-wide fuel burn and flight hours. Higher performance aircraft are the most heavily used and high-fuel consuming aircraft, but their engines are unable to operate on UL94 fully and safely.

G100UL is an emerging high-octane unleaded fuel type that has promise for use in both low- and high-performance piston-engine aircraft. In September 2022, the producers received an Approved Model List Supplemental Type Certificate from the FAA for use in all piston engine aircraft. G100UL is expected to become widely available to GA users in the next few years, but introducing a new fuel type does not come without challenges.

One of the bigger obstacles in the expanded use of unleaded AvGas is that thousands of small airports will need to invest in a second storage and dispensing system or retrofit existing systems. Another obstacle is that the producers of unleaded fuels will need to meet the demand that has been filled by 100LL, which is about a half-million gallons per day. Finally, the cost of unleaded fuels is currently about 30% greater than 100LL—however, as fuel production scales up, costs are expected to fall more in line with the current cost of 100LL.

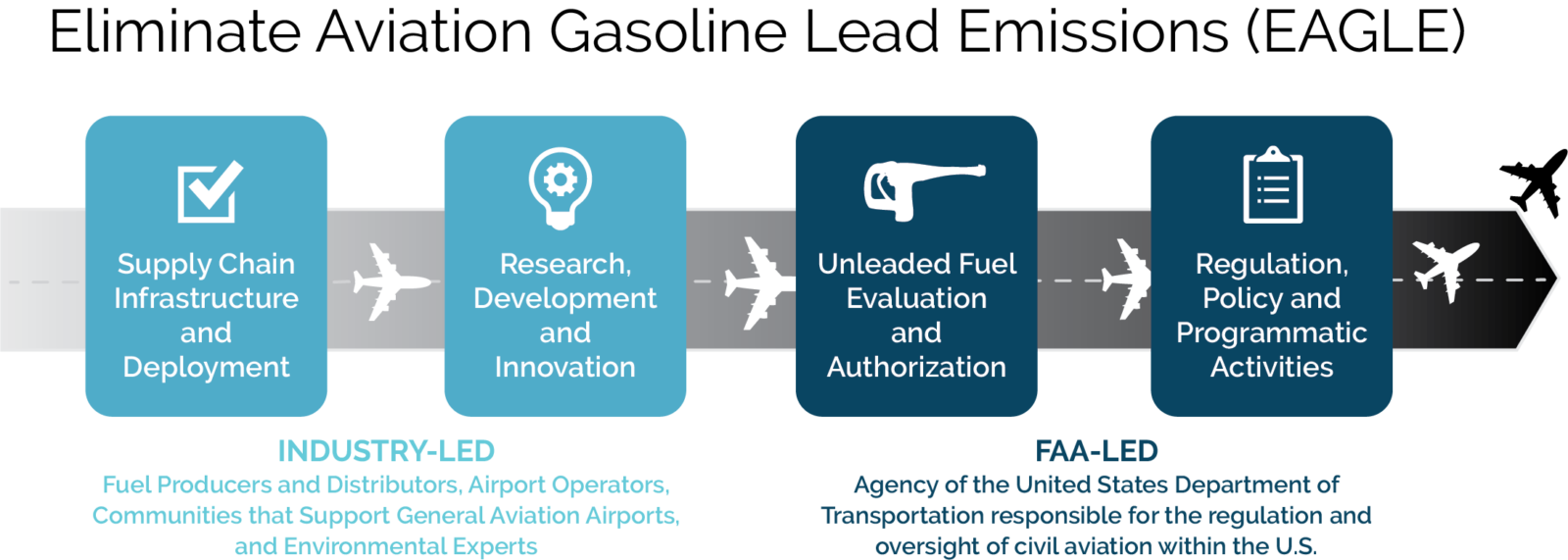

To hasten the development and availability of a high-octane unleaded fuels, the FAA recently launched the multi-layered Eliminate Aviation Gasoline Lead Emissions (EAGLE) Program with the intent to safely eliminate leaded aviation fuel by 2030 without impacting the safe and efficient operation of the piston-engine fleet.

Airports Take Action

In response to public concerns about lead emissions at GA airports, the Santa Clara County Department of Health commissioned a study to determine potential health effects of lead emissions at Reid-Hillview Airport and San Martin Airport. In 2021, the peer-reviewed study determined elevated levels of lead in children were attributable to aircraft activity at Reid-Hillview Airport. These results prompted Santa Clara County to ban the sale of 100LL AvGas at both airports after December 31, 2021.

After the ban went into effect, the FAA issued a Notice of Informal Investigation and asserted that the ban violates multiple Airport Improvement Program grant assurances, including discriminatory practices. However, in February 2023, the FAA suspended its investigation for six months as part of an agreement between the FAA and Santa Clara County officials, which includes an invitation for the two airports to participate in a program to find best practices in promoting the use of unleaded aviation fuel.

USEPA’s Endangerment Finding

On October 18, 2023, the USEPA issued an “endangerment finding” under the Clean Air Act, concluding that the “lead emissions from aircraft engines that operate on leaded fuel cause or contribute to air pollution that may reasonably be anticipated to endanger public health and welfare.” The endangerment finding triggers a statutory mandate for the EPA and FAA to develop federal regulations regarding the use of leaded aviation fuel. The FAA has publicly committed to the elimination of leaded aviation fuel by 2030, but neither the EPA nor the FAA have announced any more specific timeline for issuing new regulations regarding leaded aviation fuel. The endangerment finding does not authorize any action by state or local agencies to regulate leaded aviation fuel.

While there is broad agreement regarding the need to address the environmental and public health impacts of lead emissions, the difficulty and cost of transitioning to unleaded AvGas is seen as a significant obstacle that must be overcome. Many industry leaders stress the importance of transitioning to unleaded fuels in a manner that does not compromise the safe and efficient operation of the piston-engine fleet or transportation infrastructure.

Further, industry leaders see the value in continuing the collaborative work with government and environmental stakeholders under the FAA’s EAGLE Program before implementing strict regulatory standards. While there may be differing opinions on the regulation of AvGas and its possible implementation, stakeholders agree that safety remains the top priority in any effort to reduce lead emissions from aviation fuels.

“Fly Clean” Program

- Resources and guidance to airport operators, including information on alternative fuel options, best practices for fuel management, and technical assistance for infrastructure upgrades

- Education and outreach initiatives to raise awareness among pilots, airport operators, and other stakeholders about the benefits of using unleaded fuels and reducing lead emissions

- Incentives for airport operators that successfully implement sustainable practices, such as reduced landing fees or fuel sale discounts

By participating in the Fly Clean Program, GA airports could make a significant impact in reducing lead emissions and promoting a cleaner, more sustainable future for the aviation industry. For more information on how to address your leaded AvGas challenges, please contact Neal Wolfe.